Driveway Quality Assurance

Getting off to a solid start

It’s no good having your driveway installed if the materials being laid are not on solid ground. It will look good at first but after around one year (or in some cases even less), the poor quality and care will start to show.

For example, if you laid tarmac over soft ground and drove a car over it, the soft spots would start to show through with the ground underneath settling. After some time, the tarmac will start to crack and breakaway leaving you with a very unattractive new drive.

We generally stay away from using recycled rubble for the simple reason that it doesn’t contain enough dust to bind the stone together. What little dust is in the rubble generally consists of soil and brick dust, which wont create a solid platform on which to lay the tarmac. And it’s not uncommon to find weeds, wood and the odd shoe in there for good measure. The only time we may use recycled rubble is if we’ve had to dig down quite some way to reach solid ground, but then we would lay our 40mm crusher run on top followed by a 20mm crusher run.

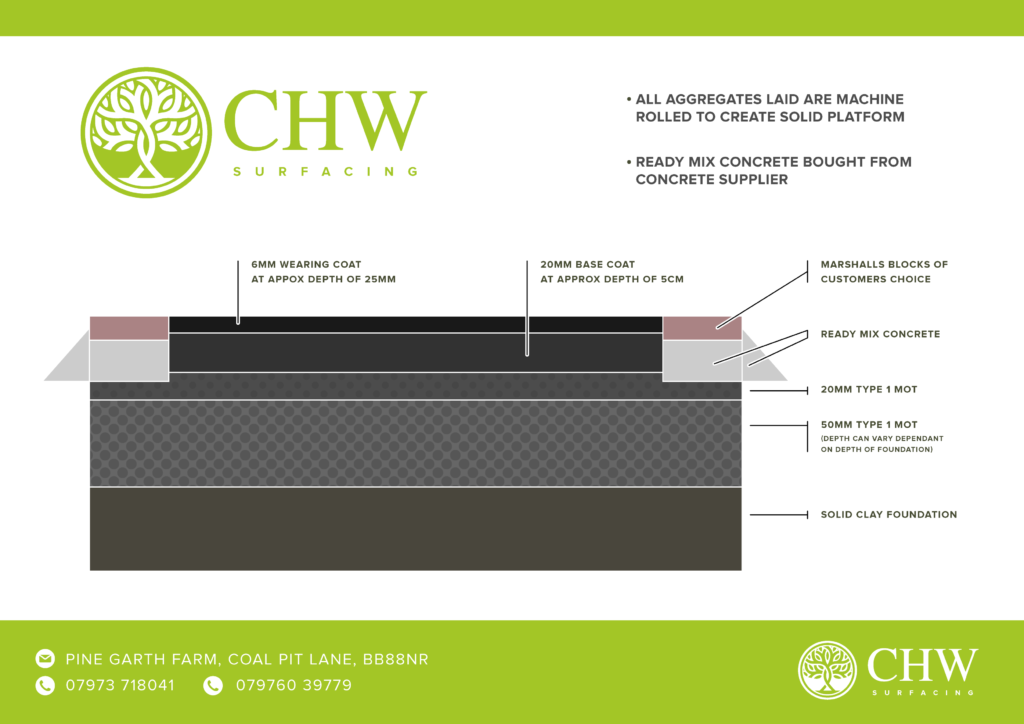

Below is a diagram to help you visualise how a perfect driveway that will last, should be installed. Click the image to zoom in.

Having the right equipment

CHW have all the experience and equipment to ensure each job gets done to the highest of standards.

Starting with the equipment, we have two 18 ton hook loading wagons that can be used for removing existing driveway gardens. We can load all waste on to the wagons, which is then emptied at the tip.

To accompany the wagons we have a 3.6 ton, 1.5 ton and a 0.75 ton digger to dig and load on to the wagons, so no matter how much waste there is we are equipped to deal with it. One of the added benefits of having our own skip wagons and diggers is that we are not relying on third parties. This makes the job run more efficiently with no skips left outside the premises of the customers property allowing us to carry on with the next step of the project.

We also own a small JCB loader for larger driveways, which comes in handy for removing waste, carrying crusher run hard-core and moving materials around the job.

Quality starts from the foundation upwards

When CHW quote you for a drive or patio that is the fixed price no matter how much waste needs to be removed. We will remove the existing driveway and then dig down to what we think is a solid foundation to work on. Sometimes you don’t have to dig down very far and others you can remove tons of soft ground until you get down to something solid.

As we mentioned earlier, it’s wrong to lay anything on soft ground as it will always show through eventually and all that money you’ve paid for having it done will be a complete waste. At CHW we are different in that once we are happy with the ground, we lay a sub-base of 40mm crush and machine rolled to create a compact foundation then generally followed by 20mm crusher run to get the area level ready for the binder course.

On a standard driveway, if a company puts a 6mm surface coat straight on top of the hard-core then alarm bells should be be ringing. The driveway will break away and crack in a matter of months.

Choosing tarmac that’s fit for its purpose

On a private driveway you need to lay a binder course of 20mm tarmac to a minimum depth of 50mm and machine roll to create a solid foundation to lay your 6mm surface coat at a minimum depth of 25mm, which is then also machine rolled to a smooth and compact finish.

We only lay Stone Mastic Asphalt (SMA) tarmacadam that has added fibres to provide more stability and prevent the tarmac tethering in the sun when turning on the spot. It is also car park grade asphalt so it can endure a lot of traffic and wear. It’s more expensive and technical to lay than standard asphalt, but it’s worth every penny and is more cost effective in the long run.

The finishing touches of quality

If you’re after something more bespoke around your driveway like a block border, cobble sett or Indian stone sett, the better quality of material that you use, the more longevity you’re going to get from your driveway.

At CHW we only use Marshalls block paving for a decorative border and if you’re after something a little different, we use hand pick cobbles and Indian stone setts .

It is important the concrete on which these materials are bedded and backed up with is key. In most cases these blocks and setts are taking a lot of traffic from your car passing over them either at the front of your driveway or in front of your garage. When you’re not laying these up against a house wall these will encase your driveway and preventing your driveway from breaking away.

A cheap alternative is recycled dust that has been screeded from broken rubble and can often have high amounts of soil and weeds along with brick and concrete dust mixed together, which is not sufficient for withstanding the pressures it will be put under.

We only use ready mix concrete that we pick ourselves, therefore we know it will be a solid lean mix and definitely sufficient for withstanding the strains it will be under; after all, they build houses on top of the materials we use!

Don’t compromise on quality for price

There’s usually a good reason some companies quote significantly cheaper than others; they use poor quality materials that simply will not last and you’ll be the one footing the bill to have the work redone. We might not be the cheapest around but what you get from CHW is guaranteed quality, professionalism, customer care and a driveway that will last.

Be vigilant when choosing your driveway company, don’t be afraid to ask questions about how they will go about the job and the materials they will use. A good place to look to verify a company is by reading their customer reviews left on third party sites like Google, Facebook , Yell and Trustpilot.

Choosing the right company can be the difference of your driveway lasting one year and twenty years.